“There was some back and forth and we’ve made a few improvements here and there. Some things we custom designed. We’ve worked on tyre equipment for many years but it’s only the past couple of years, with the export ban coming, that we’re seeing a change for this equipment. There’s certain equipment we can buy in from overseas ready to go. We can tweak that, customise and tailor it to make it more cost effective.”

Tony knows others in the tyre recycling industry who are diversifying to meet export ban requirements and is pointing them in Waste Initiatives’ direction.

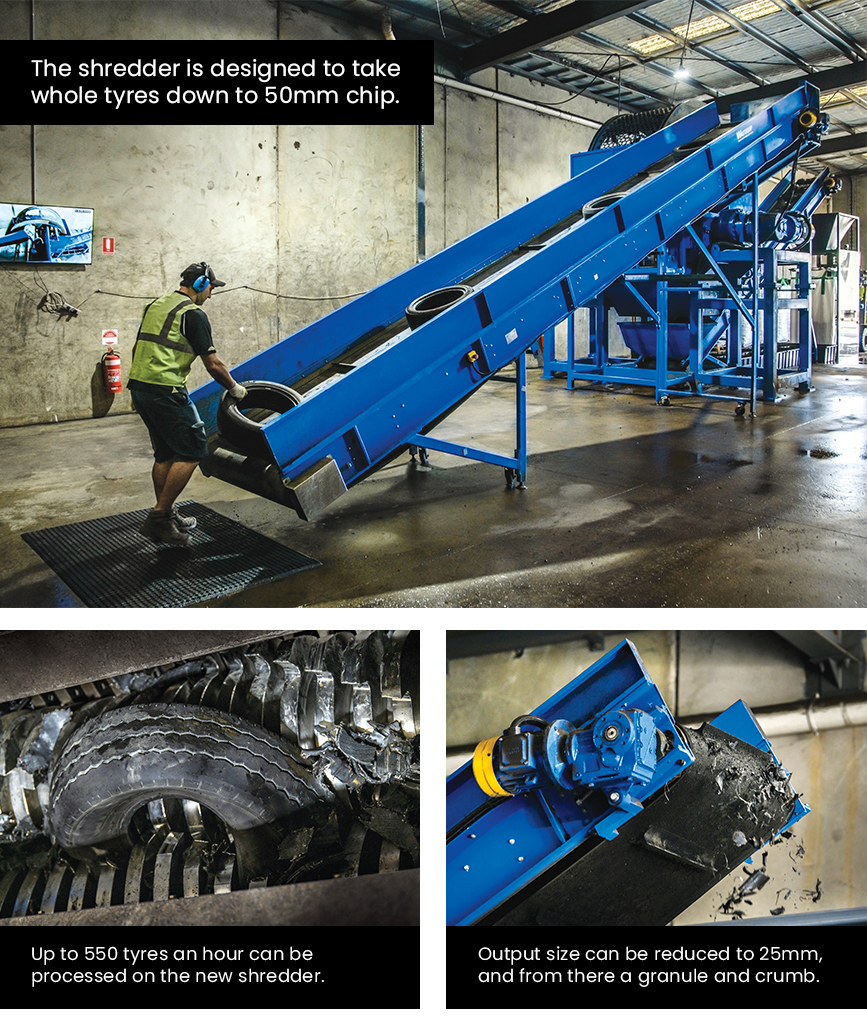

“I’m telling them if you want a machine, just ring up Jason. Waste Initiatives will be with you for the long-term. The partnership between Waste Initiatives and OzTyre Recyclers has been fantastic. “We told Jason what we wanted and how many tyres we needed to produce an hour. He came up with a lot of different options until we have the shredder we have now.

“This is an entirely new machine and, like anything developed from scratch, there’s always going to be small modifications. Waste Initiatives is great for that – we come up with ideas, they implement them. It’s a partnership that talks to each other.”

And it’s a conversation that is ongoing. Tony says Waste Initiatives regularly checks in on the performance of the shredder and is “only a phone call away”. “If we think we’ve got a problem we ring Jason. When you spend so much money on a machine, you want to take care of it today, rather than tomorrow. “I find people like Jason are willing to talk to me and understand what I want in the machinery. That helps a lot.”

The shredder has exceeded expectations. The old baling equipment was processing 400 tyres an hour and Tony wanted an equivalent workflow with the new equipment. He says they’ve gone past that to 550 tyres an hour.

The success, and world market influences including a shortage of shipping containers caused by the COVID-19 pandemic, have prompted Tony to fast track the next stage of OzTyre Recyclers’ evolution.

OzTyre Recyclers has bought forward plans to install a crumbing plant and hopes to have it operational by April 2022. Jason is currently working on designs for the plant. Unlike many tyre recyclers who are looking to sell tyre crumb to road builders, Tony is searching for a new wheelhouse.

“I’ve looked at what other areas you can use tyre crumb in,” he says. “There’s a lot of small factories and manufacturers that use actual rubber crumb.

“As members of Tyre Stewardship Australia, they have helped us with the local requirements and advised us what is happening with tyre recycling overseas. That’s what helped us order the shredder we needed.

“It’s opening my eyes to what’s happening around the world in tyre recycling. This is not just something we’re doing for today, it’s something that has to be looked at for the future.” Tyre Stewardship Australia is a product stewardship organisation that provides accreditation to tyre recyclers and collectors.

For more information visit: wasteinitiatives.hustledigital.com.au/recycling- systems/tyre-recycling/