Talk to Waste Initiatives today to find out more about our waste & recycling solutions.

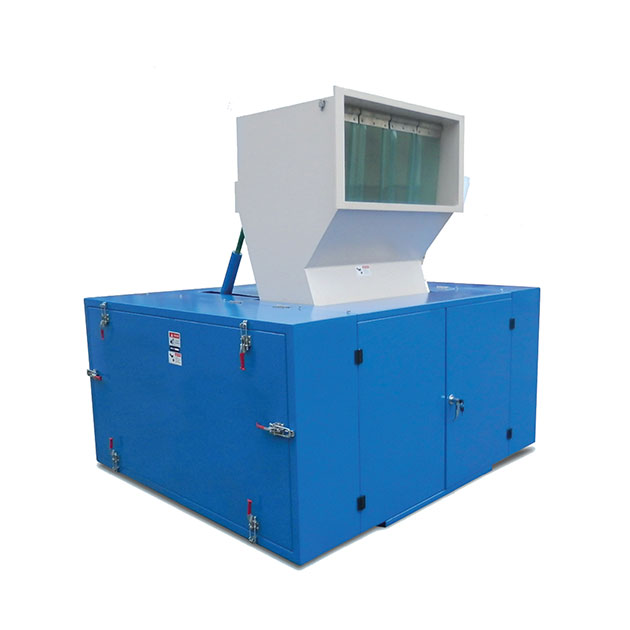

Granulators

Our PC Series granulators are designed for volume reduction and sizing of various materials.

To suit different applications and improve efficiency of granulating different materials, a selection of rotor configurations are available.

Granulators

-

PC2660

The most compact of our granulators, this is perfect for small plastic production facilities.

-

PC3260

A small to mid-sized granulator, working well on a variety of plastic products.

-

PC3280

The safe and reliable operation of this small granulator means that it will incorporate easily with your existing facilities and operations.

-

PC4280

A sturdy granulator well suited for processing plastic components, cable, plastic drums and E-waste.

-

PC42120

This mid sized granulator is sure to impress with its 55kW motor and processing capacity of up to 1T/hr.

-

PC66120

The largest of the granulators with processing up to 2T/hr. Well suited for large plastic recyclers and other recycling facilities.

Clients that trust our products

Make An Enquiry

What are plastic granulators?

- In its simplest terms, plastic granulators are large, industrial machines with powerful rotary systems designed to chop and grind scrap material (plastic) into manageable pieces of raw material called flakes or regrinds. In waste management and recycling, granulator machines are an integral piece of equipment to process plastic for recycling. It’s this finely ground raw material that is taken away and processed into ‘new’ plastics. Granulators can be classified into two of the following categories:

“Beside-the-press” Granulators – used to grind relatively small volumes of waste material and used for immediate recycling of waste material and used for immediate recyling into the processing of plastics. These granulators are generally used in injection and blow moulding processses to grind trim waste, runners and sprues. The granules are then returned into the production process automatically. The machines can also be used for inline recycling plants as well. Options include custom hopper design & sizes, infeed and outfeed including conveyors and blower cyclone extraction systems.

- “Central and Heavy duty granulators” – typically larger in size, more powerful and intended to size-reduce greater volumes of scrap from various processing lines. There is a range of sizes available offering a high quality regrind with minimal fines. They can be used in all kinds of recycling applications either as a stand-alon, single pass size reduction machine or after a shredder in an inline recycling plant to increasethroughout and size reduction results.

Contact our waste management specialists and we can provide an industrial granulator or central granulator that can be tailored specifically to meet your onsite requirements as well as your handling and loading expectations.

-

How do Granulators work?

Compared to shredders, plastic granulators operate with intensely high rotor speeds, the standard ranging from 400-500rpm and offer a relatively low torque. They primarily operate by cutting/slicing the material with internal rotor blades that take repeated small ‘bites’ to create a uniformed end product. Although many granulators work the same way, different varieties in their ‘refining’ process can subtly affect your regrind product’s end result. Granulators also differ in that they don’t have a minimum throughput.

An industrial granulator can handle thousands of plastic scraps with differently sized machines to process different materials. When it comes to cutting power, these industrial machines depend on high-horsepower motors, plus heavy flywheels to effectively dice through scrap at a consecutive, even pace. The only principle limitation experienced with granulators is that its feed opening’s specific size and shape can affect scrap capacity. Oversized waste scrap that hasn’t been adequately minimised through a shredder can get wedged in the feed opening and slow down production.

-

Granulator machines for your business

Avoiding plastic waste in this day and age is next to impossible. It comes in many forms, from plastic utensils, toys, household decorations, furniture to food packaging. If said plastic isn’t destroyed or recycled correctly, it can damage environmental effects and keep the market from creating synthetic plastics high. This is why a plastic granulator is an auxiliary piece of equipment for plastic processing facilities and any business involved in effective waste management.

While the brute force of a shredder can significantly reduce waste production, businesses require the precision and finesse of a granulator machine to turn scrap material into manageable fragments for proper plastic recycling. Often, the following two devices complement each other. Our shredder machines will perform coarse size reduction. The scrap produced from the shredder can be then fed through a granulator to turn into sizable, more consistent regrind that can then go back into plastic production.

At Waste Initiatives, we can provide your business with various rental granulator machines and assess your situation to determine the best machine for your particular processing requirements.

Contact one of our friendly team members for more information about a specific granulator.

Frequently Asked Questions

What is a granulator?

Granulators are machines that grind with applications primarily in recycling industries. Compressed air rotates the rotor to help the internal chopper break down and grind materials in these machines. In the waste industry, they often specialise in grinding plastic down into flakes, or plastic pellets.

What can the granulator be used for?

Commercial granulators are primarily used for grinding down plastic offcuts, defective shapes or other plastic waste into smaller materials that can be melted down and made into new plastic. For this reason, plastic granulation machines are a necessary fixture in any plastic production or in manufacturing. You can also use granulators to break down and grind other products such as fibres, copper cables and lightweight metals that don't contain iron (non-ferrous metals).

How much does an industrial granulator cost?

Industrial granulators pricing starts generally from $4000 and goes upwards. Enquire with our staff to get a quote and understand more how our commercial granulators can meet your requirements. As well as with the different finance and rental options Waste Initiatives provides to make these machines more accessible for businesses.

How can a granulator be useful?

Granulators grind scraps or materials (such as plastic, fibre, rubber, wood and copper cables) that would otherwise be thrown away into small pellets, flakes, powder or regrinds to be reused through recycling.

Additionally, these recycling machines have also been used to create smaller ground components from raw materials such as hay, animal feed, fertiliser, and manure to prep them for other applications.

What size of granulator should I choose?

You want to select the size of your machine depending on the type of material you are processing as well as your production needs and requirements.

Consider these factors for your desired application:

- Capacity:

- how much material do you need to process per hour?

- Screen size:

- what is the range of sizes of the materials you are going to feed into the machine?

- Feeding method:

- do you have the workers trained/on hand to look after this process if it's more on hand? (Consider getting an in-feed conveyor and/or out-feed extraction unit if you don't.)

We list these products above from smallest to largest to assist plastic recyclers and other types of refuse facilities. Starting from our compact PC2660 perfect for smaller plants, to our PC66120 made for processing up to 2 tonnes per hour.

How to maintain a granulator?

You can keep your grinding machine in good working order by following these steps: ensure you inspect and keep the knives inside the cutting chamber sharp. You should also rotate them on a regular basis to keep your knives in prime position for performance and evenly distribute the wear and tear more evenly on the machinery. Keep your eyes on the screen (or opening) of the granulator on loading. Make sure that it does not get clogged through the process as this can cause the rotary arms inside to jam and damage other components of the machine.

To keep operation smooth, also ensure that you keep the motor, bearings and other parts of the machine well oiled.

Cleaning should also be part of your maintenance routine to keep the machinery in good condition. You can find more detailed information on how to clean and properly handle each granulator listed by getting in touch with one of our staff.

Download Brochure

Download Brochure