Talk to Waste Initiatives today to find out more about our waste & recycling solutions.

Horizontal Balers

Our WastePac range of horizontal balers have been developed to meet the needs of the Australian waste industry. These high-density units provide large-scale waste generators and recycling enterprises with an effective and reliable baling solution.

From small semi-automatic (manual-tie) balers through to fully automatic channel balers we have your needs covered.

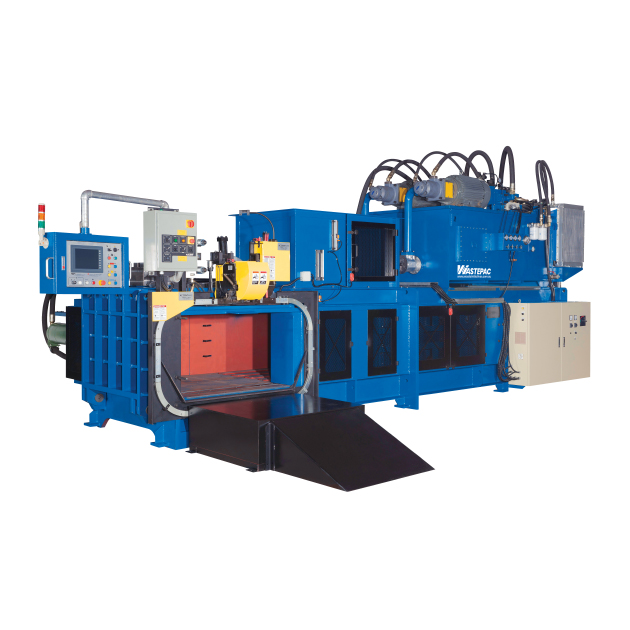

Automatic Horizontal Balers

-

CS Series

Low-capacity automatic horizontal baler suitable for industrial and logistics companies.

-

CM Series

A high-throughput automatic baler with large apertures to accept bulky feed materials without “bridging” in the hopper.

-

CL Series

The CL Series is a fantastic performer for high-throughput recycling facilities and paper mills, typically used for OCC & ONP applications.

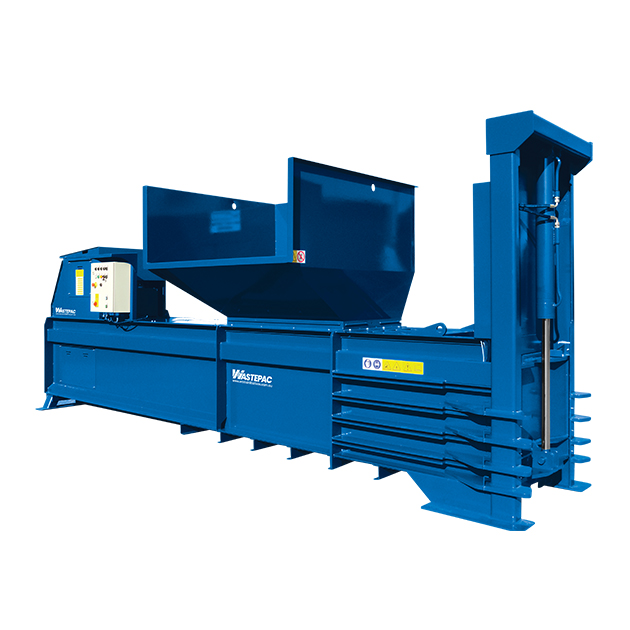

Semi-Automatic Balers

-

HX400-38T SEMI AUTOMATIC

The WastePac HX400-38T semi-automatic baler is designed to facilitate fast loading of baling materials. Producing high density and high-quality bales to improve efficiencies and drive down costs. This high force optimum density baler comes standard with full bale ejection of each bale and V shaped serrated bale chamber shear blades, making it ideal for handling a various range of applications. The WastePac HX400-38T also offers the option of custom hopper design and fit-out to suit your specific needs.

-

HX500-38T SEMI-AUTOMATIC

The WastePac HX500-38T semi-automatic baler is designed to produce high quality square edged bales up to 500kg. Designed with a feed opening allowing the loading of bulky or large items. This high-performance baler comes standard with full bale ejection of each bale and V shaped serrated bale chamber shear blades making it ideal for handling a various range of applications . The WastePac HX500-38T also offers the option of custom hopper design and fit-out to suit your specific needs.

-

HX600-50T SEMI AUTOMATIC

The WastePac HX600-50T semi-automatic baler is designed to facilitate fast loading of baling materials. Producing high density and high-quality bales to improve efficiencies and drive down costs. This high force optimum density baler comes standard with full bale ejection of each bale and V shaped serrated bale chamber shear blades, making it ideal for handling a various range of applications. The WastePac HX600-50T also offers the option of custom hopper design and fit-out to suit your specific needs.

-

HX800-65T SEMI-AUTOMATIC

The WastePac HX800-65T is our second largest semi-automatic baler with an impressive 65 Tonne compaction force. This high-performance heavy-duty baler is easy to operate and comes with all the standard features.

-

HX800-80T SEMI-AUTOMATIC

The WastePac HX800-80T is our largest semi-automatic baler with an impressive 80 Tonne compaction force. This high-performance heavy-duty baler is easy to operate and comes with all the standard features.

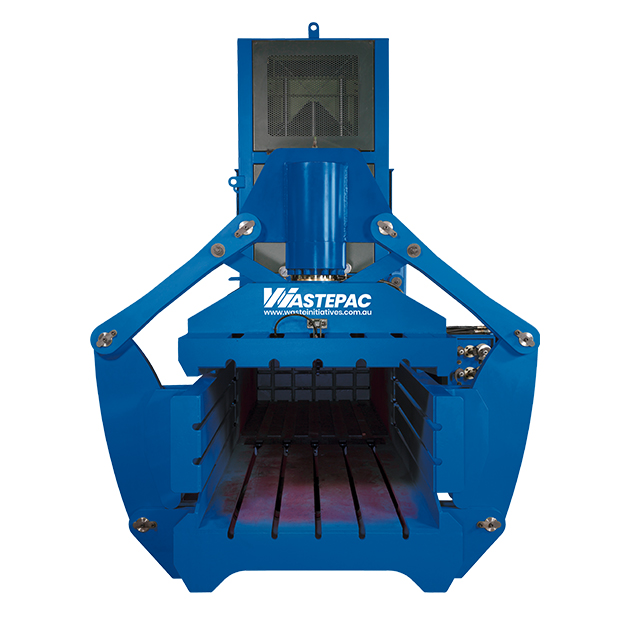

2-Ram Balers

-

TR90

Smallest of our 2-Ram balers, our WastePac TR90 suits the demands of medium-volume waste processors. Perfect for baling of rigid materials including car bumpers, E-waste, plastics, PET bottles, HDPE bottles and various other products, this high-force 2-Ram baler is built to last the distance.

-

TR120

An ultra heavy-duty baler suited to a wide range of waste materials of all shapes and sizes.

Clients that trust our products

Make An Enquiry

Horizontal Baler Machines

- Utilising years of experience in the recycling and waste management industry, the Waste Initiatives experts have provided leading Australian businesses a diverse range of innovative waste management solutions, including industry-leading horizontal balers.At present, Waste Initiatives has a vast range of powerful horizontal balers designed to process large quantities of cardboard waste, plastic and everything in between. Our products turn them into manageable bales and consequently minimise your waste output. Built by leading manufacturing company WastePac, our rental horizontal balers are adaptable for any industry, cost-effective, boost productivity, efficient and can become an integral part of your waste management plan.Our horizontal baler machines can smoothly integrate into both commercial and industrial industries, where a high volume of plastic, cardboard and materials needs to be processed, baled and transported. From sorting facilities, food factories, retail stores,regional councils offices, Waste Initiatives is bound to have the right machine to suit your requirements.

- If you’re interested in our complete product specifications and waste management services, don’t hesitate to contact our team and challenge us with your project. Alternatively, see our Baler Information Gallery and explore our full wide range of compactors and waste machine presses which can be found on our Waste Compactors page.Explore our full baler catalogue by downloading the brochure button below.

-

Our Products

Our very own WastePac range of horizontal balers have been developed to meet the needs of the Australian waste industry. These high-density units provide large-scale waste generators and recycling enterprises with an effective and reliable baling solution.

From small semi-automatic (manual-tie) balers through to fully automatic channel balers we have your needs covered.

Our classic horizontal balers are perfectly capable of handling large volumes of cardboard, aluminium cans, paper and bottles. Each is available with an optional perforator to achieve optimal results if baling PET bottles.

- If you’re looking to consistently process a higher volume of bales or looking to use this innovative waste management solution for a variety of applications, our Wastepac horizontal balers may be for you.Our balers feature the following advantages:

- Process a higher volume of bales per day than vertical baler

- Produce bales that are consistent in density and weight, making them easier to store

- Be used with in-ground or above ground conveyor belts

- Process a greater variety of materials

Frequently Asked Questions

What is a horizontal baler?

What is the difference between a vertical and horizontal baler?

How does a horizontal baler work?

What horizontal baler machine is suitable for me?

How much do horizontal balers cost?

How to maintain a baler machine?

- Air Compressor: Use an air compressor (DO NOT EXCEED 40 PSI) to blow off any debris from the baler, the hydraulic tank and any surrounding components.

- Clean behind the ramp: Materials can get behind the compressing arm in the baler, which is important to get behind and dislodge so that it doesn’t cause damage or surprise downtime to the machine. You can remove the guarding and sweep material out with a broom.

- Air Breathers: Remove them and clean them out, or replace them to help ensure a cleaner atmosphere indoors.

- Tie Slots: First move the ram to the tie position before you then turn and lock off the baler. Open the tier and use something thin enough to fit through the slots and poke to clean any excess so that your baler has a clear and unobstructed path.

- Sensors: You can also use an air compressor to blow off any debris that coats your baler’s sensors, or wipe them with a soft cloth.

Download Brochure

Download Brochure